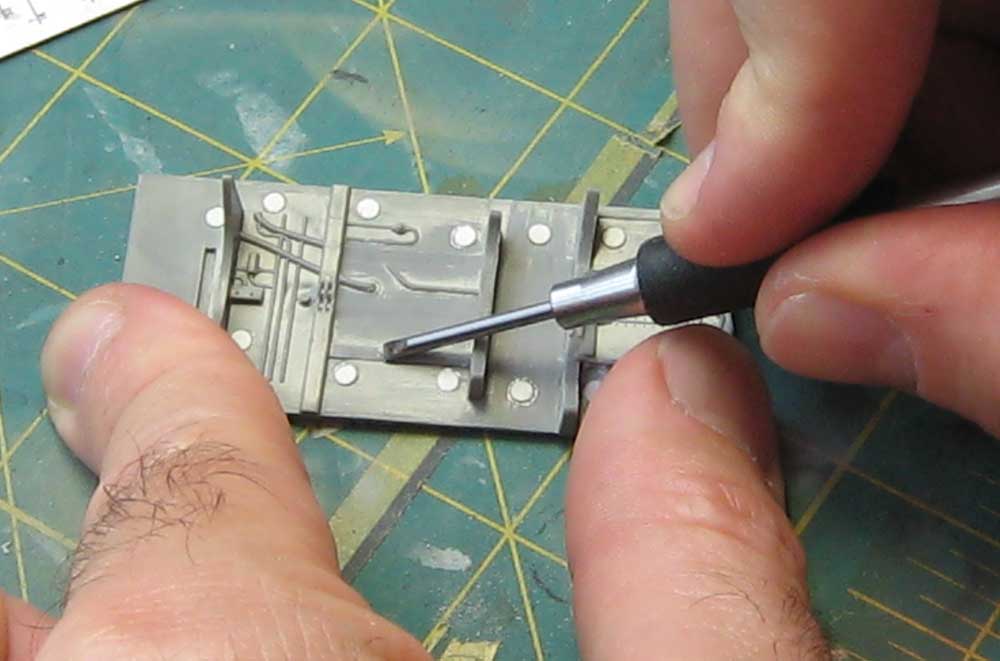

Ejector Marks

After ejection from the mould, ejector pins have clearly left visible marks on the surface of the moulding in the form of the moulding in the form of depressions,

differences in gloss or stress whitening.

Solution:

1. Ensure ejectors finish flush with the surface of the mould.

2. Optimize the changeover to hold pressure.

3. If sink marks are visible on the ejector points, increase the hold pressure.

4. If differences in gloss are visible on the ejector marks reduce the hold pressure.

5. Reduce the injection speed to minimise injection pressure.

6. Extend the cooling time and/or changeover time.

7. Ensure accurate location and movement of ejector pins.

8. Reduce the hold pressure.

9. Reduce the temperature of the mould core.

10. Use a mould release agent.

11. Check the mould for undercuts and draft.

12. Ensure adequate venting of the mould.

13. Reduce the melt processing temperature.

14. Install additional ejectors and/or enlarge the existing ones.