Jetting

From the gate point, the surface of the plastic moulding exhibits a snaking, often rough or matt strand of polymer melt.

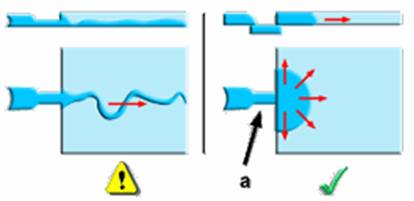

Jetting often occurs when the melt is directed from the gate into the open cavity at high local velocity.

Ideal conditions for jetting usually occur when the melt flows through a small gate into a thick section or is fired between the walls of the injection mould.

Solution:

1. Reduce the speed of injection.

2. Incorporate a obstacle in front of the gate like a pin.

3. Enlarge the gate to reduce shear.

4. Move the gate to an adjacent area where the melt is forced to flow around an obstacle or against a wall.