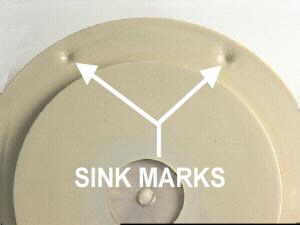

Sink Marks or Voids

Sink marks occur on the "A" surface of the moulding or bubbles form through slightly thicker regions of the part.

Solution:

1. Check if melt cushion is less than 5mm - increase.

2. Check function of the non return valve.

3. Experiment with increasing hold pressure time.

4. Increase the hold pressure.

5. Reduce the temperature of the mould.

6. Reduce the melt temperature.

7. Reduce the injection speed.

8. Extend the cooling time.

9. Increase the gate sizes.

10. Check wall thickness in the gate area.

11. Reduce the thickness of "B" surface details such as ribs and bosses.