|

|

|

Cap mould |

|

|

| Product name : Cap mould |

| Item : XS-065 |

| Details : |

· Moulds Name : Cap mould

· Moulds cavity: 2, 4, 8, 16, 32, 64, etc.

· Moulds material: 2316,718, ect.

· Moulds life: 1,000,000shots

· Runner system: Cold Runner, hot runner

· Demould system: Strip plate, motor / hydro-cylinder unscrew, ejector pins

· Moulds running: Full automatical running.

· Moulds features: Good cooling system, shot cycle time.

1. Cap material.

PP or PE. Following is the PP and PE material specification.

PP:

Polypropylene

| Processing PP |

Deg C

|

| MOLD |

10 - 60

|

| MELT |

180 - 240

|

| MAX TEMP |

300

|

| DRYING |

70 - 90

|

| INJECTION SPEED |

Medium to High

|

| PURGE |

PP

|

| STRUCTURE |

Semi Crystalline

|

| OPACITY |

Clear to Opaque

|

| PHYSICAL |

Tough, Rigid

|

| SG |

0.85 - 0.95

|

| SHRINKAGE |

1.2 to 1.7%

|

| MELTING POINT |

100

|

| HDT |

71 - 115

|

| SERVICE TEMP |

85

|

Description

|

PP offers excellent processing, good surface finish and food contact approval.

Applications include: automotive interior, exterior, house hold and medical applications.

|

HDPE:

High Density Polyethylene

| Processing HDPE |

Deg C

|

| MOLD |

20 - 60

|

| MELT |

180 - 250

|

| MAX TEMP |

280

|

| DRYING |

80 - rarely

|

| INJECTION SPEED |

Medium to High

|

| PURGE |

HDPE

|

| STRUCTURE |

Crystalline

|

| OPACITY |

Translucent to Opaque

|

| PHYSICAL |

Tough, Waxy Surface

|

| SG |

0.97

|

| SHRINKAGE |

1.0 - 2.0%

|

| MELTING POINT |

100

|

| HDT |

60 - 90

|

| SERVICE TEMP |

84

|

Description

|

HDPE is generally easy to process, with higher molecular weight grades having stiffer flow properties.

Applications include: Containers, Storage, seals & closures.

|

2. Cap mould design.

We use ug, autocad and cimatron to design the cap and cap mould.

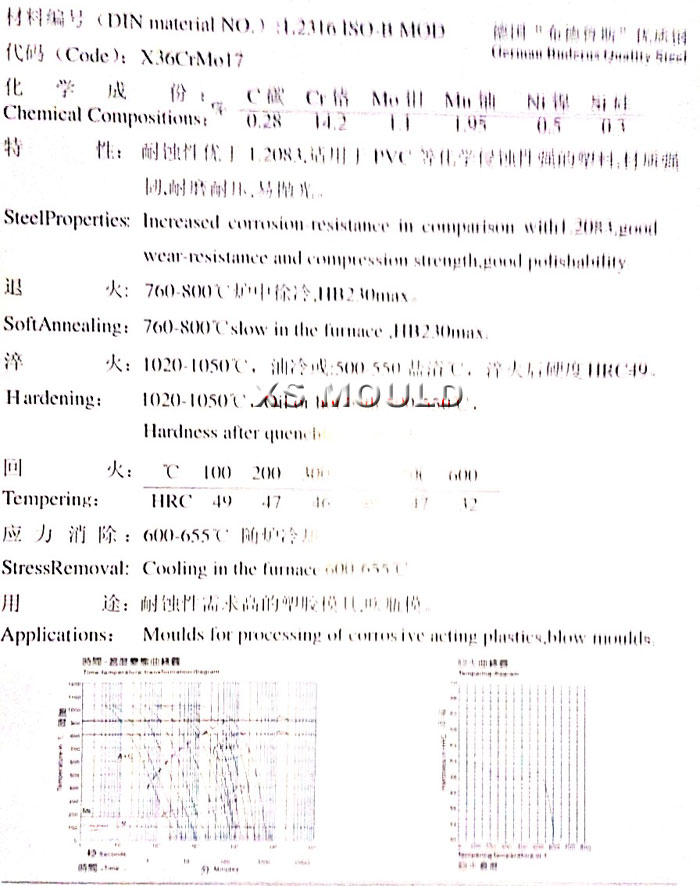

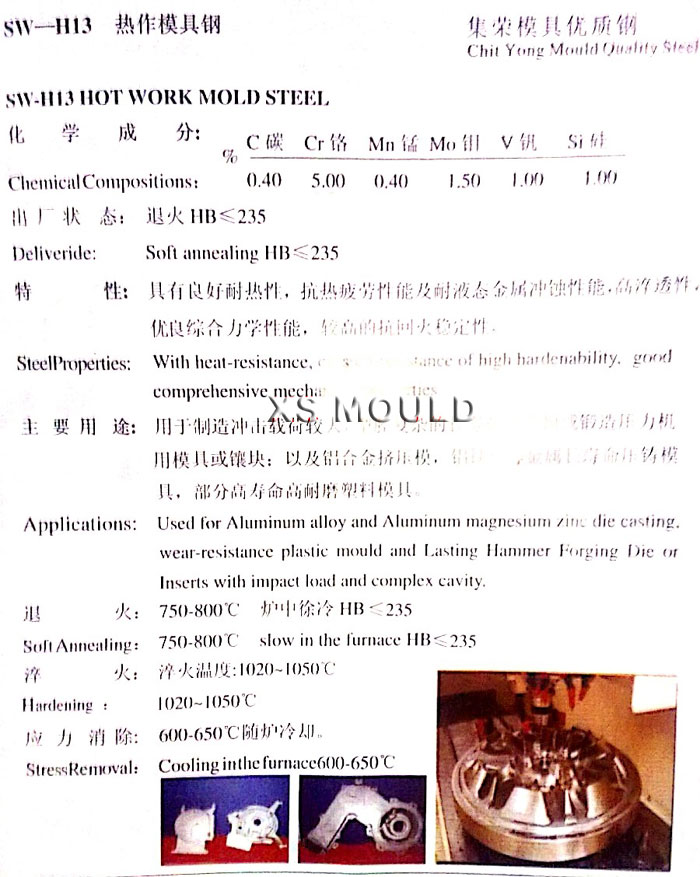

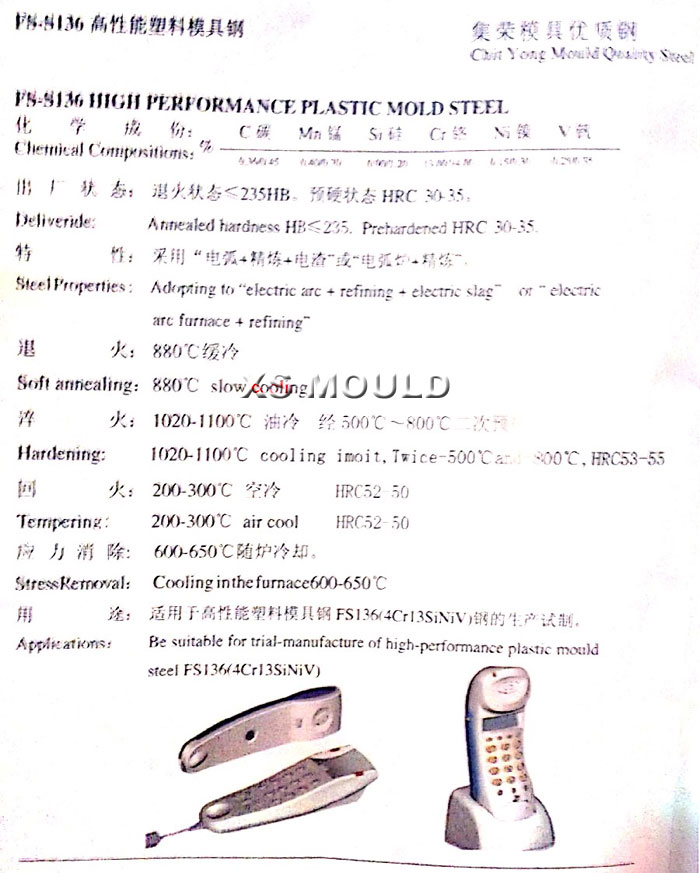

3. Cap mould material.

a. insert core and cavity: 2316, H13, S136, etc.

b. mould base: S45C. Order from LKM, KJ, etc, standard mould base supplier. Mostly we use the mould base made by ourslef.

c. mould standard spare parts: Jinghong, Punch, Hasco, etc.

d. A&B plate: 718, P20, etc.

2316 mould steel specification

H13 mold steel specification

S136 mould steel specification.

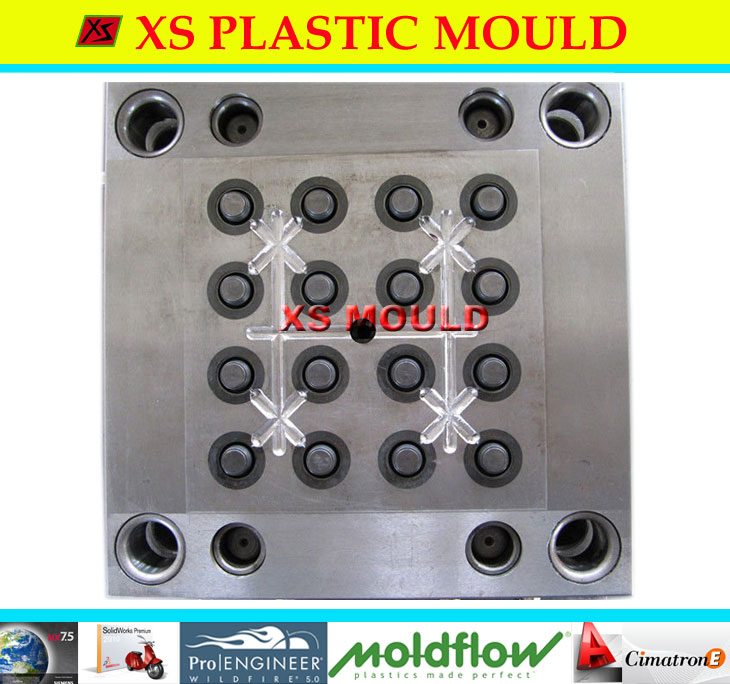

4. Cap mould cavity no.

Big size cap, mould can be 2, 4, 6, etc. cavities. For small cap, mould cavity no. can be 8, 12, 16, 24, 32, etc. Depends on the customer's injection machine.

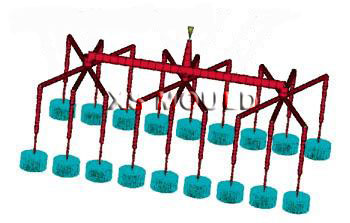

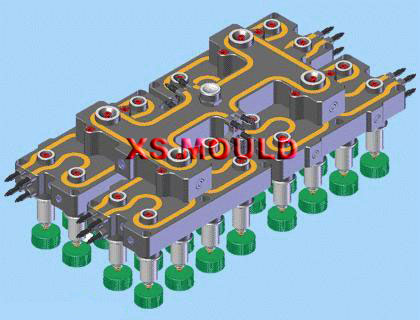

5. Cap mould runner system.

Cap mould can be designed with hot runner system and cold runner system.

Cap mould cold runner system sketch.

Cap mould hot runner system sketch.

About Xs Plastic Mould Co., Limited.

a.24hours service.

b.reply customer's email within 2 hours working time.

c.provide quotation within 2 working days.

d.provide mould steel certification.

e.provide the mould tooling status report 1 time each week.

Cap mould process.

|

1.Design/sample

|

Product, mould, etc.

|

|

↓

|

|

2.Discussion

|

Mould material,cavity number,price,runner,payment,etc.

|

|

↓

|

|

3.Order placed

|

According drawing or sample.

|

|

↓

|

|

4.Design mould

|

We will send mould design to customer for confirmation

|

|

↓

|

|

5.Mould tooling

|

We start to make mould after mould design confirmed

|

|

↓

|

|

6.Mould processing

|

Send pictures to customer to let customer what we doing

|

|

↓

|

|

7.Mould shot trial

|

Send mould shot trial samples to customer to confirm mould quality

|

|

↓

|

|

8.Delivery

|

Ship mould after mould quality confirmed.

|

Cap mould picture.

16 cavity hot runner cap mould

Oil container cap mould

16 cavity cold runner side gate cap mould

Xs Plastic Mould Factory feature.

|

|

←[Previous : XS-066]

|

|