|

|

|

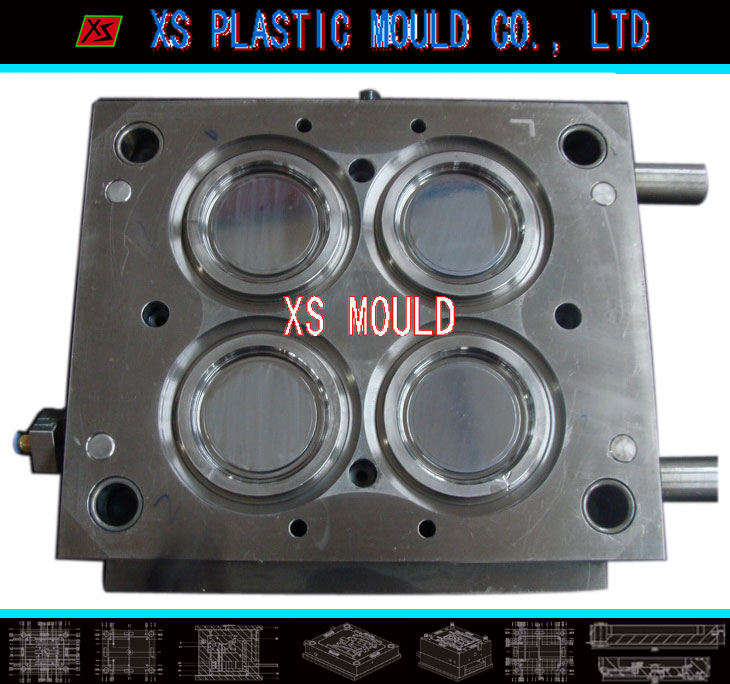

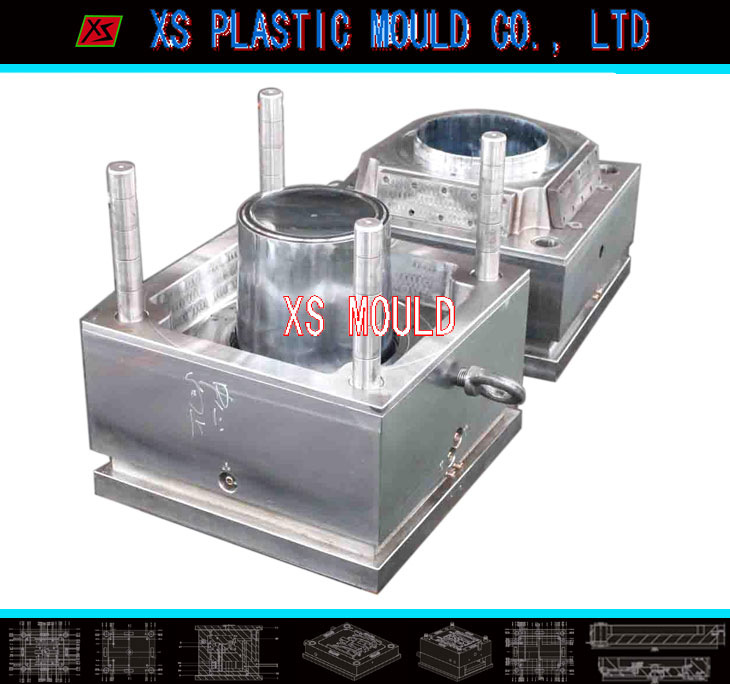

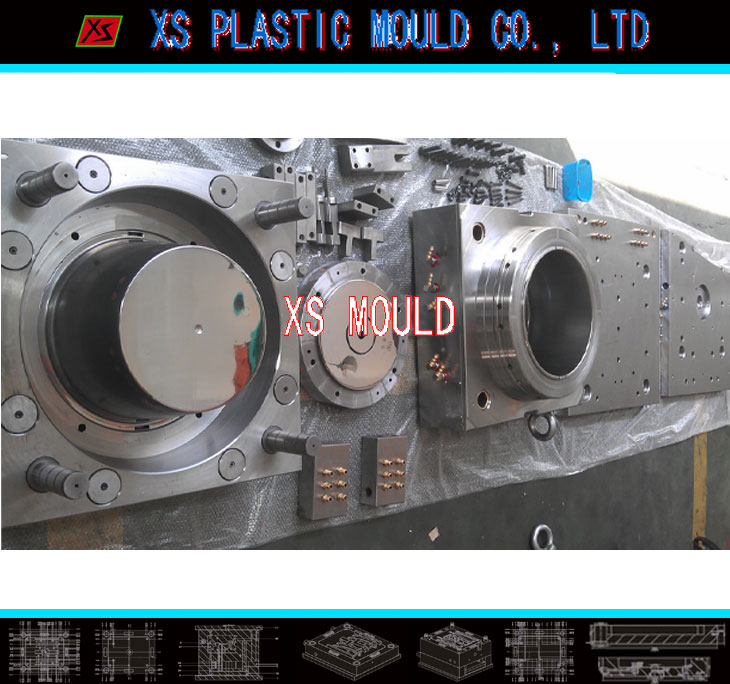

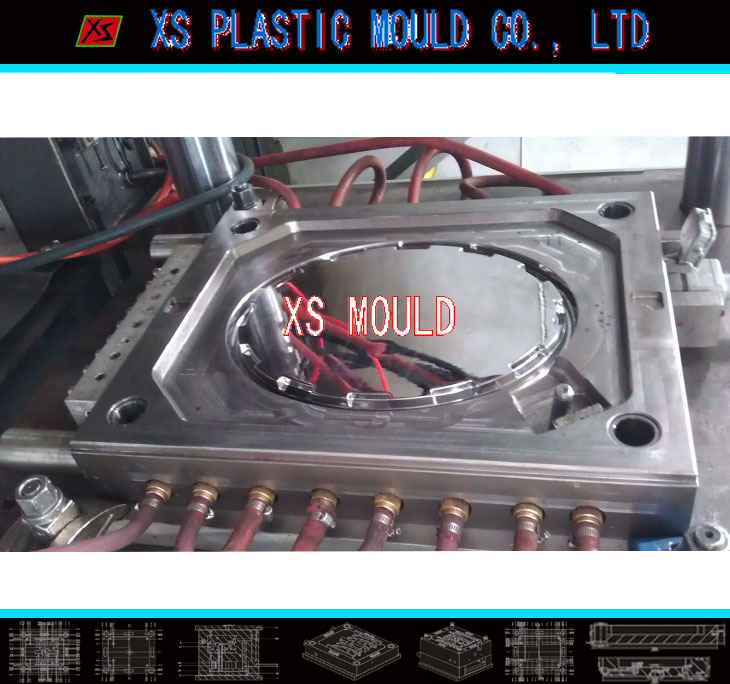

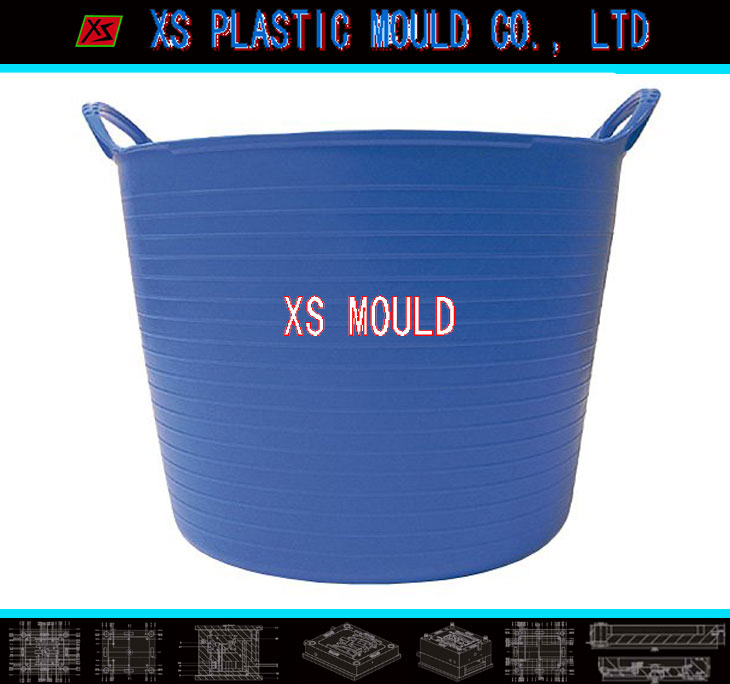

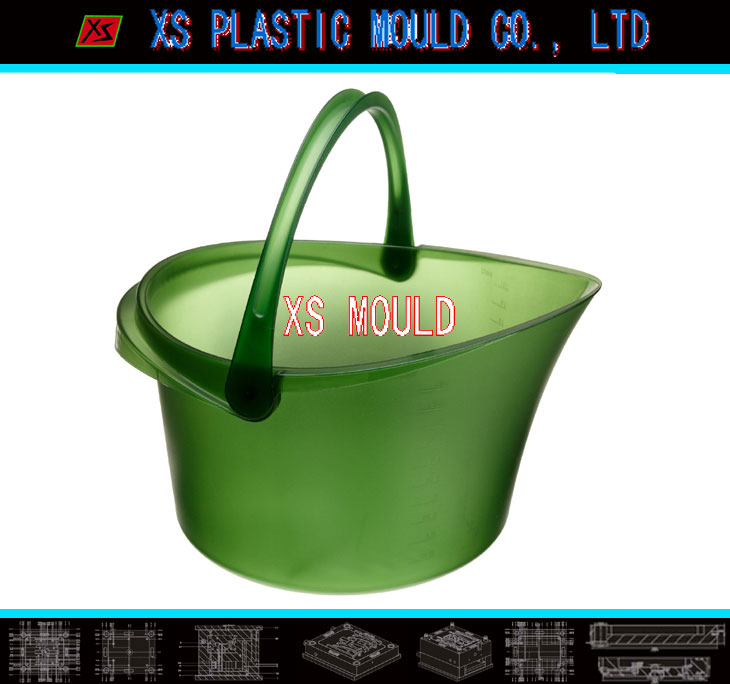

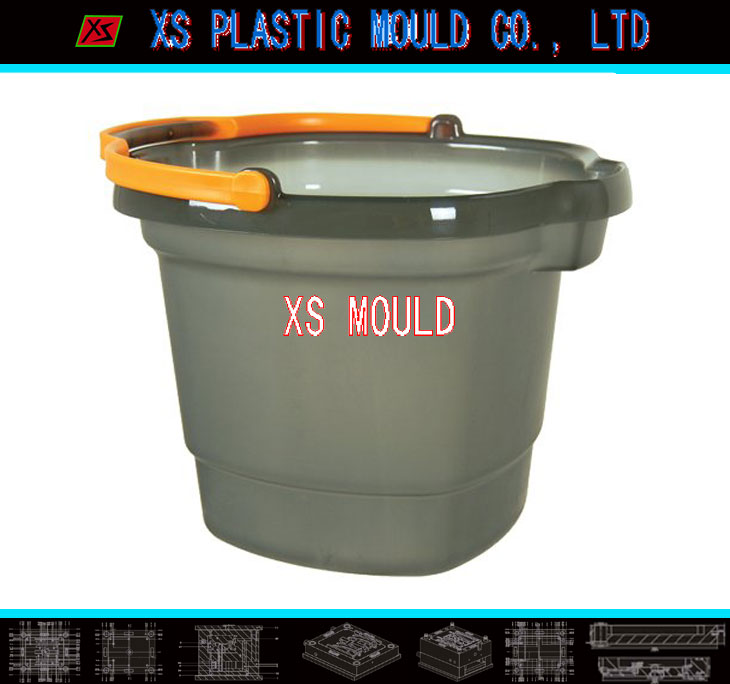

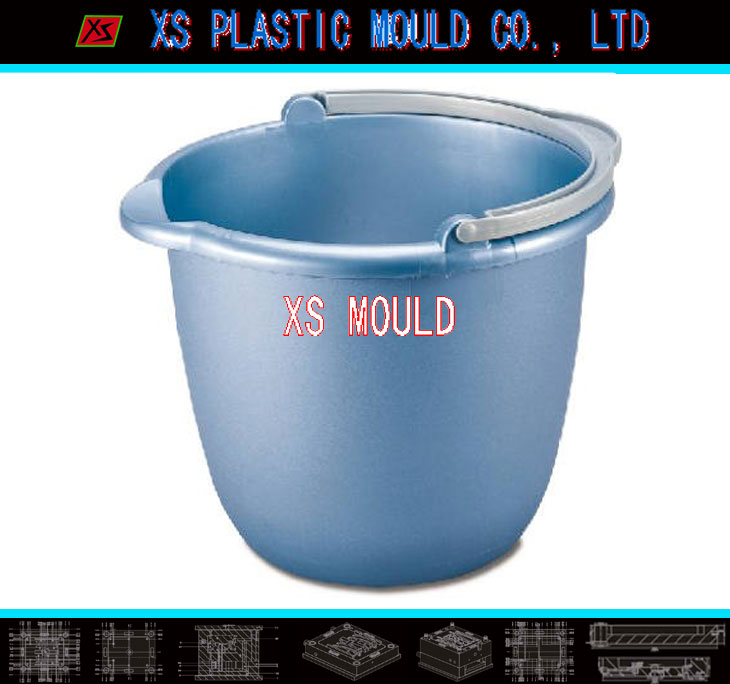

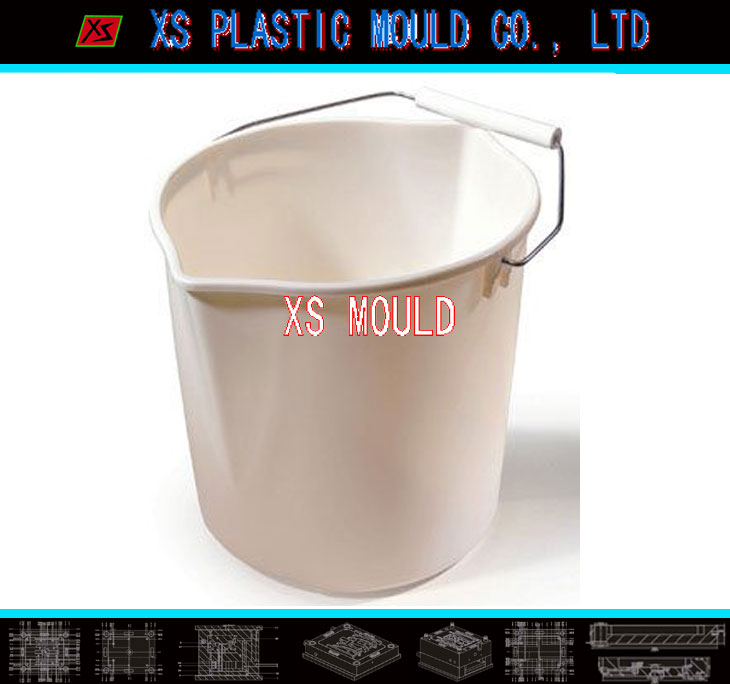

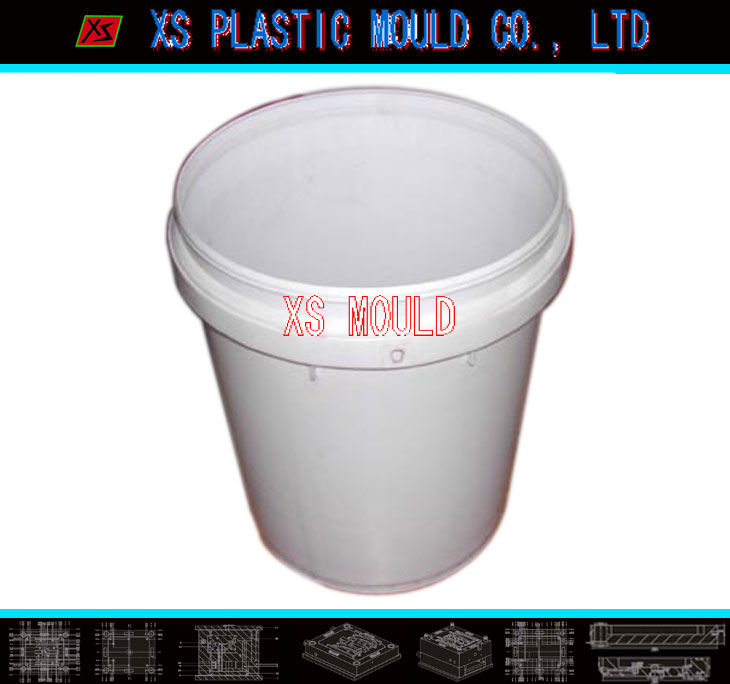

Paint bucket mould |

|

|

| Product name : Paint bucket mould |

| Item : XS-015 |

| Details : |

· Moulds Name : Paint bucket mould

· Moulds cavity: 1, 2

· Moulds material: P20,718, 1.2738, H13, BeCu, S45C (tempering)

· Moulds life: 300,000shots to 1,000,000shots

· Runner system: Cold Runner, hot runner

· Demould system: Strip plate, air ejector, ejector pins

· Moulds running: Full automatical

· Moulds features: 2 plates mould, hot runner system mould, good cooling system

· Part material: PP, PE

Please click below link to see the mould design video.

http://youtu.be/fJBoNsyitZ0

Paint Bucket Mould designed and manufactured for injection moulding plastic paint bucket. Paint Bucket Mould designed and manufactured for injection moulding plastic paint bucket.

1. Paint bucket material.

PP

Polypropylene

| Processing PP |

Deg C

|

| MOLD |

10 - 60

|

| MELT |

180 - 240

|

| MAX TEMP |

300

|

| DRYING |

70 - 90

|

| INJECTION SPEED |

Medium to High

|

| PURGE |

PP

|

| STRUCTURE |

Semi Crystalline

|

| OPACITY |

Clear to Opaque

|

| PHYSICAL |

Tough, Rigid

|

| SG |

0.85 - 0.95

|

| SHRINKAGE |

1.2 to 1.7%

|

| MELTING POINT |

100

|

| HDT |

71 - 115

|

| SERVICE TEMP |

85

|

Description

|

PP offers excellent processing, good surface finish and food contact approval.

Applications include: automotive interior, exterior, house hold and medical applications.

|

2. Paint bucket mould design software.

We use ug, cimatron and autocad to make the part design and mould design. And if necessary we will analyse the mould design with moldflow software.

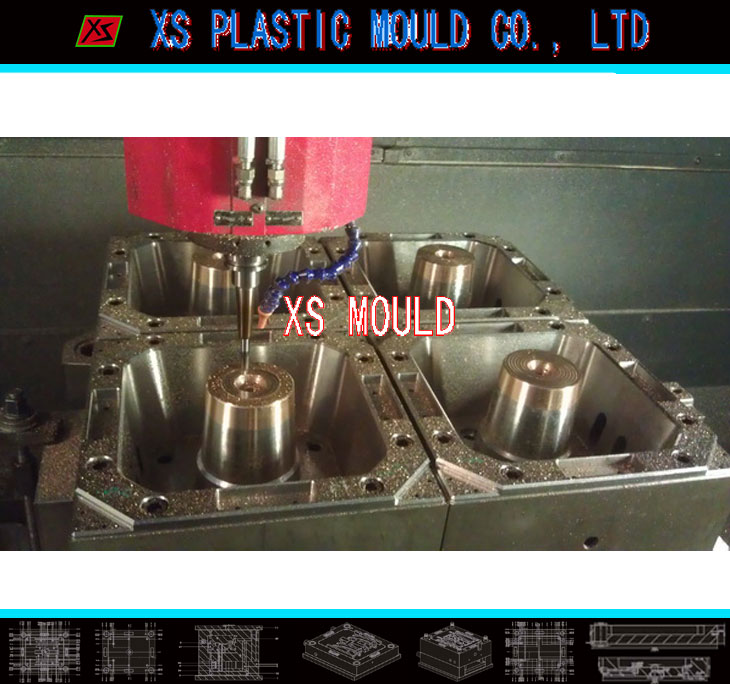

3. Paint bucket mould material.

Mould core and cavity can be made by P20, 718, H13, etc. And if customer requst, we will insert CuBe on the mould core and cavity to get better cooling to make the cycle time shorter, but the mould cost will be increased.

a. P20

Widely used to make bucket mould, mould life around 300,000shots. Mould price is lower than 718 and H13 steel.

b. 718

Mould life around 500,000shots.

c. H13

Harden steel, mould life minimum 1,000,000shots.

d. Mould base.

S45C steel. We can self make the mould base, use standard mould base, such as LKM, etc.

4. Paint bucket mould cavity no.

1, 2, or 4. Depends on the bucket size and customer's injection machine ton.

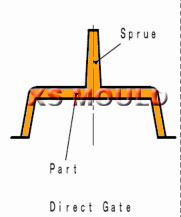

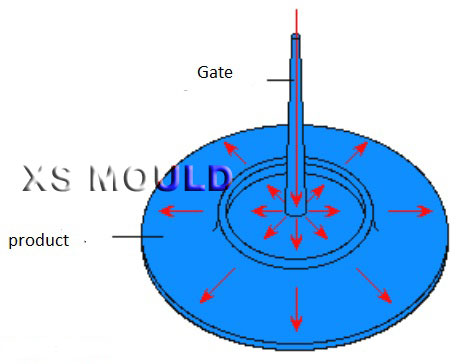

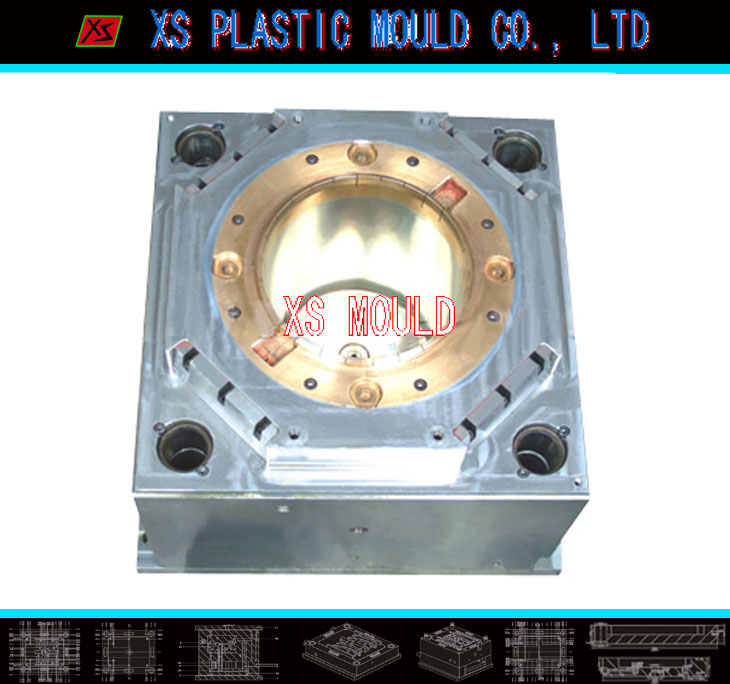

5. Paint bucket mould runner system.

More than 90% with cold runner system, rest with hot runner system. Usually paint bucket mould designed with cold runner directly gate, sprue directly on the part. Below picture as an example.

About Xs Plastic Mould Co., Limited.

About Xs Plastic Mould Co., Limited.

a.24hours service.

b.reply customer's email within 2 hours working time.

c.provide quotation within 2 working days.

d.provide mould steel certification.

e.provide the mould tooling status report 1 time each week.

Paint bucket mould process.

|

1.Design/sample

|

Product, mould, etc.

|

|

↓

|

|

2.Discussion

|

Mould material,cavity number,price,runner,payment,etc.

|

|

↓

|

|

3.Order placed

|

According drawing or sample.

|

|

↓

|

|

4.Design mould

|

We will send mould design to customer for confirmation

|

|

↓

|

|

5.Mould tooling

|

We start to make mould after mould design confirmed

|

|

↓

|

|

6.Mould processing

|

Send pictures to customer to let customer what we doing

|

|

↓

|

|

7.Mould shot trial

|

Send mould shot trial samples to customer to confirm mould quality

|

|

↓

|

|

8.Delivery

|

Ship mould after mould quality confirmed.

|

Paint bucket mould picture.

|

|

←[Previous : XS-016]

[Next : XS-014]→

|

|