|

|

|

Preform mould |

|

|

| Product name : Preform mould |

| Item : XS-102 |

| Details : |

· Moulds Name : Preform mould

· Moulds cavity: 1, 2, 4, 8, 16, 32, 64, etc.

· Moulds material: 2316, BeCu, ect.

· Moulds life: 1,000,000shots

· Runner system: Hot runner, hot plate, air sealed pin point valve gate hot runner

· Demould system: Strip plate

· Moulds running: Full automatical running.

· Moulds features: Good cooling system, short cycle time, slider

· Part material: PET, PC

1. Preform material

Mainly preform made with PET material, some made by PC material. PET usually used to produce package

application products, such as mineral water bottle & beverage bottle. PC wide used to produce led covers.

PET:

Polyethylene Terephthalate (Polyester)

|

Processing PET

|

Deg C

|

|

MOLD

|

20 - 120

|

|

MELT

|

280 - 310

|

|

MAX TEMP

|

340

|

|

DRYING

|

135 - 160

|

|

INJECTION SPEED

|

Medium to High

|

|

PURGE

|

HDPE, PS

|

|

STRUCTURE

|

Crystalline / Amorphous

|

|

OPACITY

|

Clear or Opaque

|

|

PHYSICAL

|

Rigid Stable

|

|

SG

|

1.34

|

|

SHRINKAGE

|

2.1 - 2.5%

|

|

MELTING POINT

|

250

|

|

HDT

|

70 - 80

|

|

SERVICE TEMP

|

74

|

Description

|

PET resin belongs to the thermoplastic polyester classs of plastics. Currently, the

fastest growing use is for food, beverage, and non food packaging

applications.

Applications: PET is used in beverage, food and other liquid containers; engineering

applications, often in combination with glass fiber. |

PC:

|

Processing PC

|

Deg C

|

|

MOLD

|

80 - 120

|

|

MELT

|

280 - 320

|

|

MAX TEMP

|

320

|

|

DRYING

|

100 - 120

|

|

INJECTION SPEED

|

Typically High

|

|

PURGE

|

HDPE, PMMA, GPPS

|

|

STRUCTURE

|

Amorphous

|

|

OPACITY

|

Transparent

|

|

PHYSICAL

|

Very Tough

|

|

SG

|

1.21

|

|

SHRINKAGE

|

0.2 to 0.8%

|

|

MELTING POINT

|

220

|

|

HDT

|

100-138

|

|

SERVICE TEMP

|

120

|

Description

|

Polycarbonate is strong, stiff, hard, transparent and maintains its properties over

a wide range of temperature and can be used in high temperature applications.

Applications include: automotive headlamps, glazing, electrical appliance housings,

CD’s, DVD’s & medical applications. |

2. Preform mould material.

A. We use 2316, etc. stainless and hardened steel as the mould core and cavity material. We also can use

BeCu as the core and cavity according customer's request. BeCu as mould core and cavity can make the

cooling more effective to shorten cycling time.

B. Mould base S45C steel. We can use LKM, etc. standard mould base according customer's request.

3. Equipment for tooling preform mould.

Include cutting machine, fly cutting machine, grinding machine, EDW, lathe, drilling machine, etc. Core and cavity will be high

polished to make sure the injection molded preform part with good surface finish.

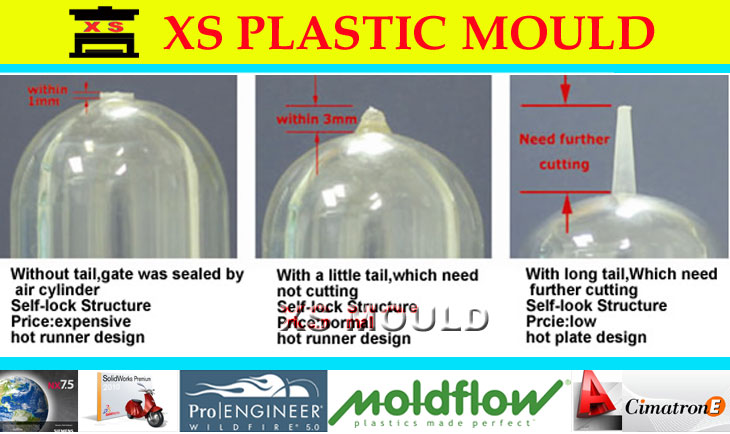

4. Preform mould runner system.

As below picture, there are mainly three different type of gate for preform mould. We can make mould according customer's

request on this.

5. PET preform mould video.

http://youtu.be/iTSTHtQK1nY

6. Package.

Wooden case. Export standard wooden case.

Description Description

|

|

←[Previous : XS-103]

[Next : XS-101]→

|

|